There are many other electric motor components that can wear out orīecome damaged over time, so a thorough servicing may require additional steps. Repair service, all of these steps may not be needed or may be in different Liner insulation to prevent contact between the core and coils.ĭepending on the type of electric motor and the scope of the Once cleaned, a repair technician applies insulation paint and installs The stator and other components need to be thoroughlyĬleaned to prevent contamination from reducing the efficiency of your electric Other specialized tools are used to clean the rest of the windings and remove Next, theįaulty winding is carefully removed in order to replace it. Setup of your motor and recording any damage that may be present. Rewinding a motor uses these basic steps:ĭata recording involves carefully cataloging the current As part of your routine maintenance, it is important to work with an EASA accredited electric motor rewinding shop with extensive in-house capabilities. Shorted, grounded or damaged coils reduce the efficiency of your electric motor until it fails altogether. “By looking at which clients and what motors are promising.As your electric motor ages, the coils can break down and become compromised.

“We plan to grow gradually by choosing our clients," Hoshina said. Because the machines are complicated and made by hand, merely adding more workers wouldn’t work, he said. was among the pioneers in developing hairpin-winding technology.Įven though the market is getting bigger, Odawara Engineering will focus on developing innovations instead of rushing to add capacity, according to Hoshina. Instead of round wires, square-shaped wires are used to pack more into electric motors, improving their efficiency and performance. In order to fit more wire into motors, Odawara is working on “hairpin" winding machines.

and China’s Changzhou Jinkang Precision Mechanism Co. Odawara Engineering also competes with Tana Automation Co., Nittoku Co. ABB Ltd and Thyssenkrupp AG have joined CWIEME, a global trade and expo group for coil winding and electric motors. In 2018, Germany’s Schaeffler AG bought Elmotec Statomat GmbH & Co., a winding technology company.

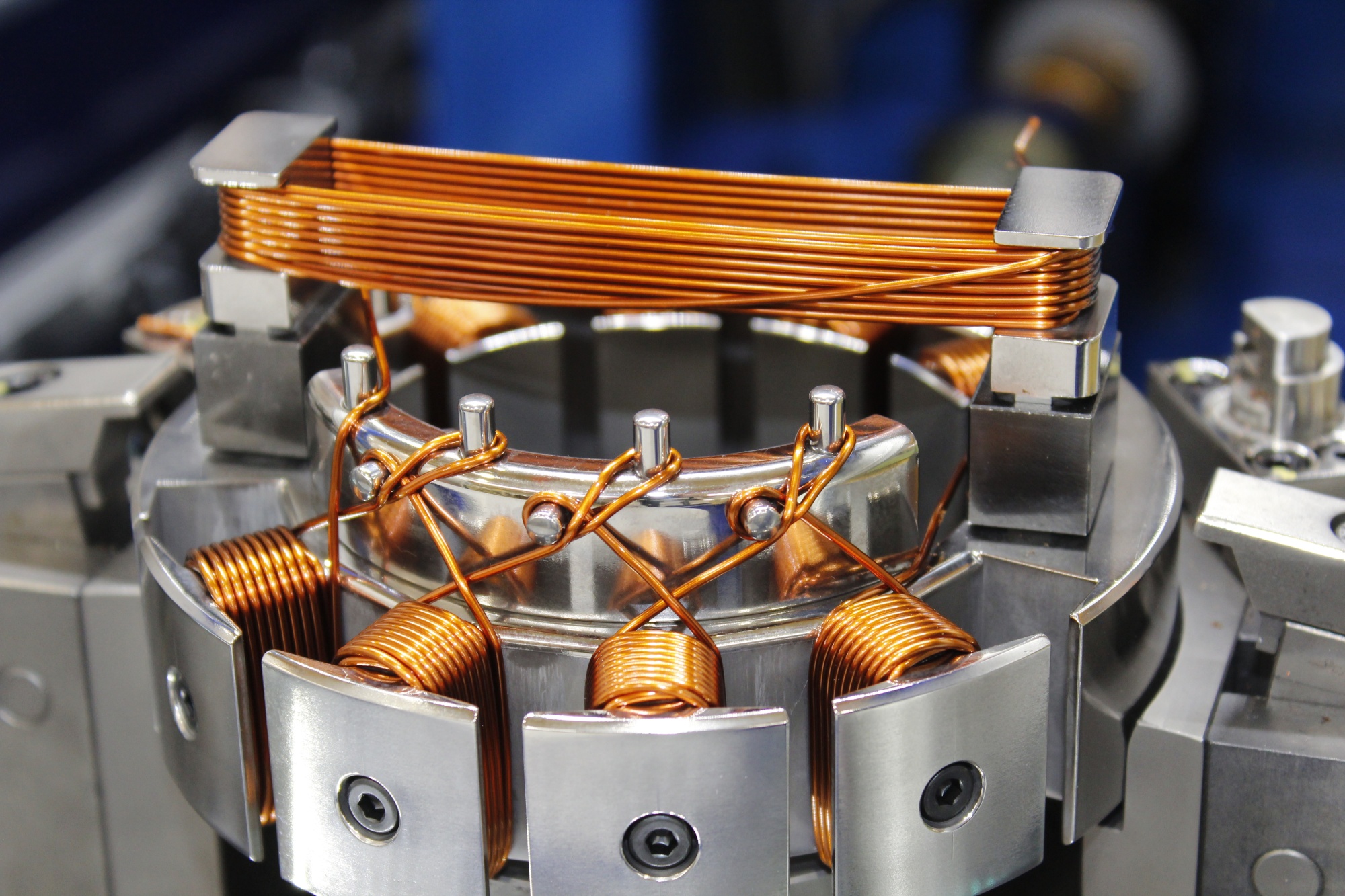

Bigger companies in the sector are buying smaller ones, and competition is becoming more global, he said. Odawara Engineering’s Hoshina said the company’s backlog for coil-winding machines has increased since December, and he said the manufacturer is now focused on cutting costs. Its sales will likely be in line with its outlook." “The company probably won’t be impacted by the coronavirus as much. “The shift toward electrification and automation won’t change" even during the pandemic, said Akihiko Kawazoe, an analyst at Toyo Securities. The company maintained its forecast for operating profit of 700 million yen ($6.5 million) and revenue of 14.5 billion yen intact when it reported results in May, as the Covid-19 outbreak shuttered economies across the globe. Robust demand for Odawara Engineering’s machines means it will probably keep its outlook intact for the current year. In 2018, Tesla made up 12% of Odawara Engineering’s sales, but in 2019 that probably slipped below 10%, the threshold for reporting such figures. Apart from Tesla, the company also counts Toyota Motor Corp. Located in Odawara, a city about 90 kilometers (56 miles) west of Tokyo, the company’s prime business during Japan’s postwar economic boom was building coil-winding machines for makers of refrigerators and air conditioners. “Our clients can’t win if they can’t differentiate their products."Įlectromagnetic coils interact with magnets to turn electric energy into motion, the basic principle behind the motors that power everything from drills to commuter trains. “We have to keep making our machines better," said Masahiko Hoshina, vice president at Odawara Engineering.

0 kommentar(er)

0 kommentar(er)